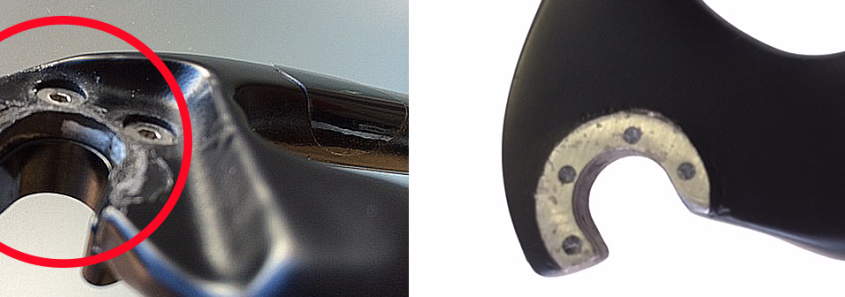

CLAMPING PROBLEMS ON CARBON DROP-OUTS

In my opinion a carbon drop-out is a vulnerable and silly design for a modern frame. You might already be aware that I don’t like this design. It might keep the pros happy but we can’t chuck our frames away as readily.

Carbon Bike Repair Ltd

Carbon Bike Repair Ltd

Carbon Bike Repair Ltd

Carbon Bike Repair Ltd