First true monocoque out of a mould in one piece

‘Fortune favours the brave’

If you are not familiar with Carbon Bike Repair, we are the largest inspection, repair and restoration service with 12 years and 16,000 bikes restored in the UK and 6 years in South Africa producing a combined output of over 20,000 bikes of almost every brand and discipline produced. We have 90% all major brand endorsement with dealership support where ever we operate.

So it is a privilege to be approached by notable bike companies to review their carbon creations. Our reputation and experience of frame failures and paint provide real value with respect to the development of new bikes and most importantly committed cost and customer value.

For example when a bike is manufactured batches are tested to meet certain performance and structural criteria which must meet specific warranty terms. This is not to exclude the graphic and paint processes which must withstand 2 years of exposure under warranty.

However not all tests can simulate the real world. Time and exposure also play a role in the success of a particular bicycle. Certain external criteria such as varying rider physiology, environmental challenges and competency play a large part in the success or failure of a bike in the market place. This cannot be simulated as we see all too clearly every day. It is easy to see mistakes in hindsight.

Therefore we advise on glaring and not-so-obvious potential structural failures as well as performance and maintenance improvements. Another important benefit is batch testing to ensure problematic bikes are identified for reasons only identified by design tweaking and poor governance at the factories.

As mentioned previously, a large part of our evaluation process includes application techniques on finishes and special effects such as candy, metallic, flip paints, matt or heat application decals and foil based decals. This can be a very real issue for the brands. We assist in finding practical solutions from our experience as bike restorers.

So it is fantastic that Carbon Bike Repair’s exposure to many good and bad ideas are being recognised as valuable support and not criticism.

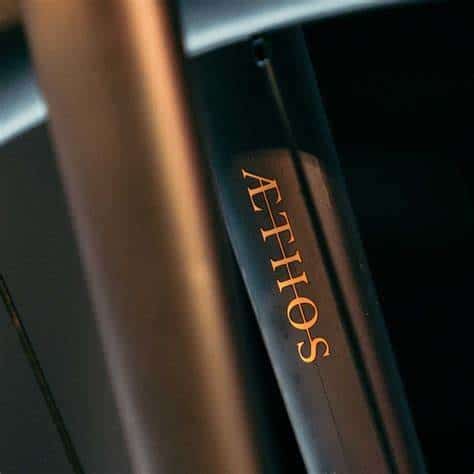

Swiss based bike brand is entering the market

When SWI met with CBR they understood quickly what we could offer them. The designer himself flew over to ensure, before any assessments were performed, that we understood their aim. For us this is fundamental in aligning ourselves with the vision of the brand.

SWI made claims to be the first true monocoque out of a mould in one piece. That might sound like an odd pronouncement considering the term ‘monocoque’ has been a brand phrase for many years when in fact they are bonded lugged bikes.

Why is a true monocoque an advantage?

Because of the structural stiffness of a pure unbroken carbon thread construction from back to front. Simply put, this achieves a notable increase in stiffness relative to mass as well as a more visceral and connected sense of performance. A true monocoque also limits the potential of epoxy bonded lug failures which are warrantable in many cases.

The process of evaluation includes a high definition scan to ensure consistency of alignment and potential mould warpage minimisations. The frame set is physically dissected to review wall thickness optimisation, composite compression conditions in the mid sections as well as in the compressed areas around seat clamps and fork steerer crowns in particular.

As a result we made significant observations to improve the SWI bike. This included amplifying performance opportunities by changing some of the DNA of the construction. I look forward to the ISO tests in Germany to see if indeed SWI is able to receive the green light for production of this impressive Monocoque bicycle.

Please contact Carbon Bike Repair to discuss similar reviews of conceptual and current carbon product.