News & advice

Thermoplastic Bikes: The Future Is Here

We need to talk about what is coming.

To some, it might not seem like a huge leap — certainly not as dramatic as the arrival of carbon fibre or aluminium back in the day. But this is different. I’m convinced we’re on the cusp of a major evolution in bicycle construction.

Before I get ahead of myself, here’s the gist:

Repairing Carbon Wheels

Wheel designers obviously calculate all the maths to make a wheel fit for purpose but unlike a repaired frame it is only deemed fit for purpose when it comes out of the mould and receives it’s trued spoke set. There are still many areas we can repair so stick around as I explain the complexities of wheels.

Metallic vs Candy – What is the difference?

Candy colours use a metallic undercoat (Like silver or gold) while having a tinted transparent top coat to create the desired colour. Whereas Metallic finishes use powdered metal in the paint to reflect more light.

Seat Post or Frame? Where to clamp your Bike

Keeping in mind that clamps are designed for round tubing, some frames have oval, square, or other non-round tubing. Making it difficult to clamp on the frame.

Fork Steerers – Are they Repairable?

Firstly I need to make a point about manufacturing carbon steerers. As repairers we have the unenviable task of finding safe ways to repair unnecessary problems which occur due to the improper use of carbon fibre on components. This is only one of many areas of a bike we note. I guess I shouldn’t complain but in many ways repairing the problem does not solve it so we become part of the problem in a way.

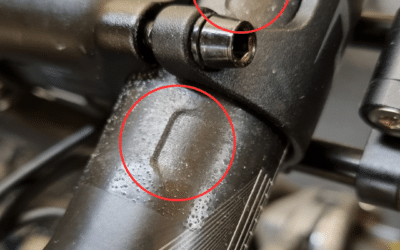

Indents On My Handlebars – Is this a fracture?

Have you noticed strange dents on the handlebars when removed from the stem? Some bikes show a groove around the clamp-on front mech collar, or seat post clamp pinch on the collar. These can all be causes for concern so let me explain what is going on.

High Modulus Frames – Are they better?

To explain whether high modulus carbon fibre frames are better or not, we need to know what the difference is between Low Modulus Carbon Fibre and High Modulus Carbon Fibre.

Cycling Your Bike In Winter – Is it bad?

We don’t know about you but we like riding our favourite bike whatever the weather!

Colour Matching – How we do it

There’s a reason that colour matching is so challenging. We are not given any colour codes by the manufacturers and even if we were as soon as the paint is exposed to sunlight, it starts to change.

current workshop lead times

1Week

health checks

1 – 2 Weeks

carbon repair

(no restore – stripped frame)

4 – 5 Weeks

carbon repair & paint restore

(2 Weeks – Express service on demand)

frequently asked questions

How to box your Bike for travel

- Create a ‘soft’ frame around the bike to avoid contact with the frame itself.

- Covering the surfaces with non-abrasive padding to avoid abrasion and additional impacts

Where to ship or drop off your Bike

WE REQUIRE FULLY STRIPPED FRAMES ( all components off) PLEASE.

Opening times: Weekdays between 8:00 – 16:30 (earlier by appointment)

Address: Unit 1a Bridge works, Kingston road, Leatherhead KT22 7SU located down the side road after the Leatherhead car wash

Tel: +44 (0)1372 372 766

Saturdays our partner shops would all be happy to receive your frame on our behalf, please call ahead to make an appointment.

Please see our list of trusted partners below for drop off and/or should you need help with mechanical work: